In CHINA BBP CO., LTD, the white lined chipboards are widely used to produce the cost-effective paper printed boxes and corrugated printed boxes. And the grey boards are widely used for the gift paper boxes and rigid paper boxes.

The grey board is a kind of paperboard that is completely made of the recycled paper pulp. The name comes from its natural grey color. The grey board varies from 0.1-2.5mm in thickness. They are widely used to make the luxury rigid set up box.

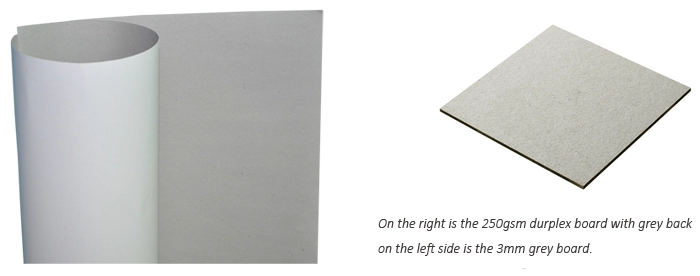

It is called white lined chipboard when the greyboard is coated with the white clay. Therefore, it is also called clay coated white back paperboard, referred to as CCNB. In China, some people call it duplex board with the grey back. They are actually the same thing. They white lined chipboard are usually no more than 0.6mm. The grammage varies from 250gsm to 450gsm.

The white lined chipboard is widely used to make the paper folding boxes and litho-laminated carton boxes. It is litho offset printed and then glued to the single faced corrugated board on the production line to create a corrugated box with fine printing.

Meantime, the greyboard can also be double side coated to have the white lined chipboard with the white back.

The 350gsm, 450gsm CCNB paperboard are widely used to produce the various custom paper printed boxes. Because it is made of the recycled paper pulp, it is quite cost effective compared with the solid bleached paperboard which is made of the kraft paper pulp. The printed paper boxes are mainly used as retail packaging boxes and toy packaging boxes.

The red printed paper box above is a food take out paper box. It is made of the 350gsm white lined chipboard, which has the CMYK full color printing and glossy UV varnishing.

The green paper box above is a cat food packaging box, which has the bag style with the auto locked bottom. On the top is the double sided tape which is used for the closure of the paper box.

Copyright by CHINA BBP CO., LTD. All rights reserved.