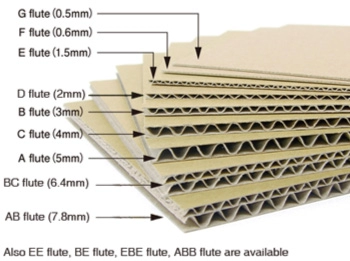

As A Good China corrugated box manufacturer, CHINA BBP CO., LTD supply the corrugated printed box with the E flute, F flute, B flute, C flute, A flute, BC flute, BE flute, BA flute, EE flute, EF flute, EBA flute, ABA flute. Meantime, we also produce the micro flute corrugated boxes, including the N flute corrugated box and G flute corrugated box.

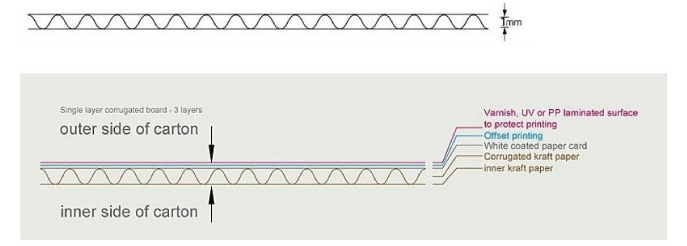

Corrugated board is made of the front surface linerboard, back surface linerboard and the corrugated medium(fluting). The corrugated boards are excellent and ideal for the corrugated shipping boxes, cartons, corrugated mailer boxes when strength and durability are needed and for printed folding boxes when exquisite printing is needed

The E flute, F flute corrugated printed box is one of our most featured corrugated box products. Besides, we also supply the custom corrugated box printed inside and outside. Also, the corrugated board can be used to make the various custom corrugated display boxes, stand, diecut boxes and corrugated tray.

The linerboard are either made of virgin pulp, called kraftliner, or of recycled pulp, called testliner. For the outer surface of the brown corrugated shipping box, the kraft liner are usually used to provide the good strength and color tone. When an exquisite outer printing surface is needed, the outer surface brown kraft liner is replaced by the white lined chipboard. The white lined chipboard has the white coating, which is smooth for the fine printing. The grammage of the linerboards comes with 120gsm, 140gsm, 170gsm, 200gsm, 230gsm.

Fluting is generally produced using waste based fluting medium, semi-chemical fluting medium is used for enhanced properties. There are a number of common flute profiles or sizes. Flutes come in five basic heights and shapes - the most common are "B-Flute"(used for die-cut boxes) and "C-Flute (used for RSCs). B-flute is compressed and appears thinner, but don't be fooled. It is made with more paper to provide stronger side wall protection from blows and punctures. C-flute is taller, with more air space, but offers enhanced stacking strength. For excellent graphic reproduction, consider E-flute. And the grammage of the fluting paper comes with 95gsm, 105gsm, 120gsm, 140gsm, 170gsm

The micro flute corrugated board particularly refers to the E flute, F flute corrugated board, as well as the G flute, N flute, O flute corrugated board. The flute height is less than 1.1mm. The micro flute corrugated boxes are lighter weight and smaller volume, which are easier for packing, shipping and storage. The F flute and G flute corrugated boxes are the prefered choice for the cosmetic paper boxes and pharm paper boxes, as well as some other custom printed paper boxes.

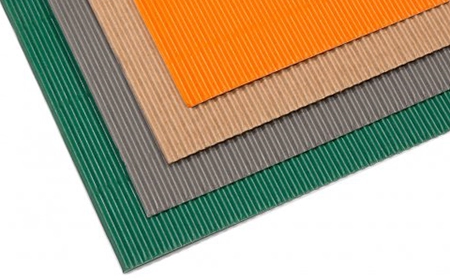

Compared with the E flute, the micro flute paper box offers enhanced printability. They are easier to fold and die cut. Compared with the foling boxboard, they are stronger, offering the better rigidity and durability.

Also, the colored micro flute corrugated boards are used as the inserts inside the cosmetic paper boxes and some other gift paper boxes.

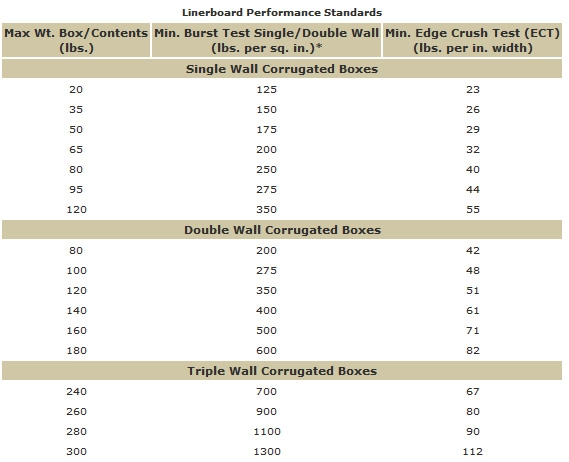

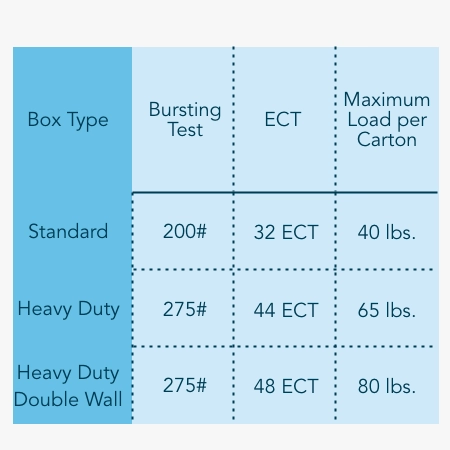

The strength of a corrugated box starts with its material. The flute, when anchored to the linerboards with a starched-based adhesive, resists bending and pressure from all directions. When placed vertically on its ends, the flutes form vertical columns, capable of supporting considerable amounts of weight.The amount of virgin pulp fibers and the length of those fibers in a corrugated sheet substantially contribute to box strength. For example, the difference between a 200# test box and a 275# test box is that the latter has more pulp fibers in its corrugated linerboard. The 200# test box is rated to hold up to 65 lbs. of box and contents while the 275# box can hold up to 95 lbs. A 350# test box is rated to hold up to 120 lbs. of box and contents. The following chart shows Bursting Test and Edge Crush Test performance standards of corrugated box liners based on the combined weight of a box and its contents.In CHINA BBP CO., LTD, we supply the heavy duty corrugated cartons, shipping cartons.

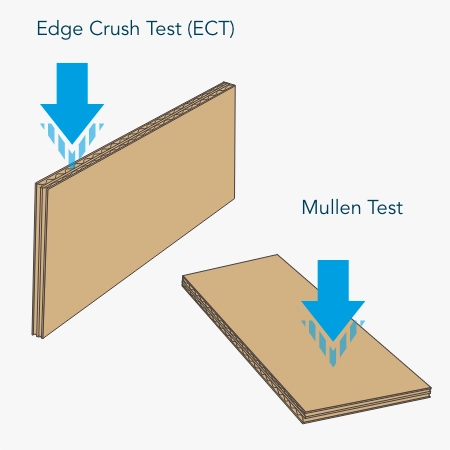

There are mainly two methods to test the corrugated printed box strength. One is the Mullen test, the other is the Edge Crush Test.

The Mullen Burst Test measures the force required to puncture the face of corrugated board and is reported in pounds per square inch (psi), boards are thus rated accordingly eg #275.

Since the approval of corrugated board as the valid shipping materials in 1903, the corrugated boxes have played an important role in the products shipping, distribution and storage. To ensure the strength, the Mullen test, i.e., Burst Strength test, Burst test was developed.

The Mullen test is a measure of the force, or the pressure that is required to puncture or rupture the face, or wall of the corrugated board. This burst strength data is got by the Mullen tester, in pounds per square inches (200# Test, 275# Test, etc.). The most commonly used corrugated carton conforms to the 200# Test. The higher the number, the stronger the corrugated box.

ECT, which stands for Edge Crush Test, is a measure of the edgewise compressive strength of corrugated board. It is measured by compressing a predefined section of board on its edge between two rigid platens.

In 1990, supply chains became increasingly automated and corrugated cartons were stacked high on pallets in the containers for sea shipping. The concerns about the box strength shifts to the stacking performance. The Burst test is very useful to estimate the resistance of a corrugated box to an internal or external impact in a rough-handling environment. However, the Mullen burst test provides no clue to the box stacking strength which is essential to the safe sea shipping and warehouse storage. Therefore, a new strength test, the Edge Crush Test was developed to provide a way to determine the "strength" of a corrugated box as it relates to stacking, or Box Compression strength (also referred to as BCT or Box Compression Test strength). And it soon got the global more widely acceptance.

Edge Crush Test is often abbreviated to ECT. It is a more efficient measure than Mullen test when stacking strength is the primary concern. It is measured by compressing a small segment of corrugated board on edge between two rigid plates perpendicular to the direction of the flutes until a peak load is established. The test result, or data is also measured in pounds per square inches and is reported as an ECT value (for example, 32 ECT).

In short, the ECT tells you how much top and bottom pressure a box can withstand before crushing. The most commonly used corrugated boxes in the industry will be 32 ECT. 200# Test and 32 ECT Test are widely accepted as interchangeable.

Usually a round, sometimes square stamp is printed on the bottom flaps of the corrugated cartons. This stamp is the Manufacturer's Certification Stamp and ensures that the manufacturer has produced a carton box that adheres to the regulations of the U.S. Commerce Commission.

Copyright by CHINA BBP CO., LTD. All rights reserved.