The slotted carton boxes are the most common styles and structures of the corrugated printed box. Slotted box styles are generally made from one or more pieces of corrugated board. The board is cut on the die-cutting machine to permit folding. The die-cutter creates a joint at the point where one side panel and one end panel are brought together. Boxes are then shipped flat to the factory for the product packaging. In the factory, the workers assemble the box, put inside the products and close the flaps. The International Fibreboard Case Code refers to these styles as Slotted-Type Carton Boxes, while the carrier classifications call them Conventional Slotted Carton Boxes.

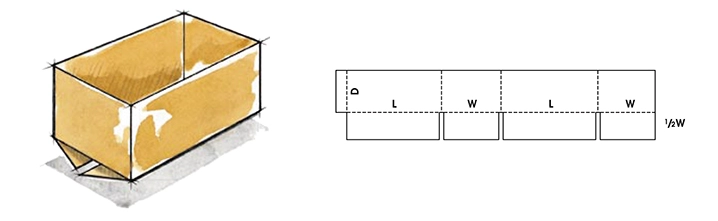

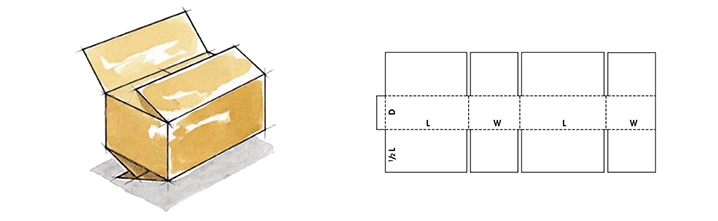

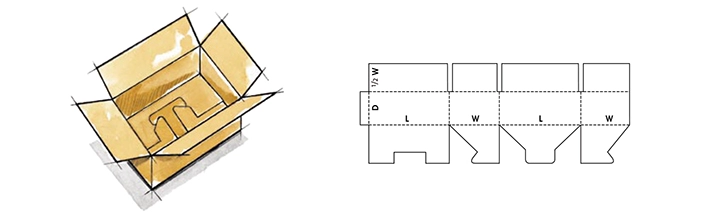

The HSC carton box style is the same as Regular Slotted Carton (0201) described below without the top set of flaps.

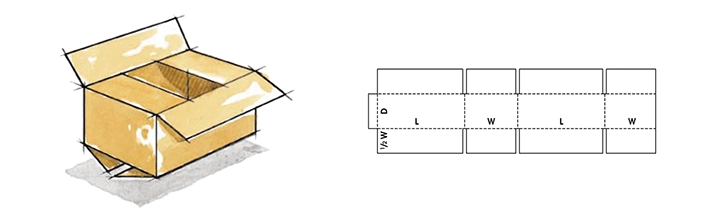

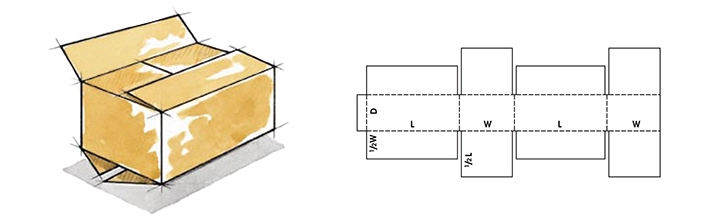

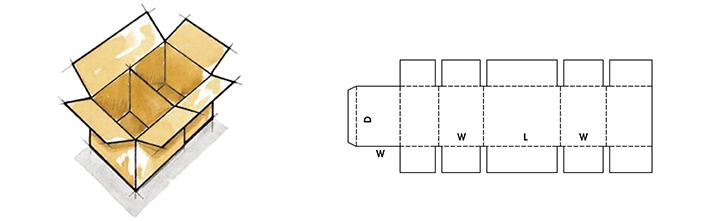

The RSC corrugated box is a typical corrugated shipping box, which is very cost effective for the packing and shipping of the goods in most industries. All flaps of the carton have the equal length, and the two outer lengthwise flaps are one-half the box's width, so that they meet at the center of the box when folded. If the product demands a flat, smooth and even bottom surface, or the protection of two full layers corrugated board, a fill-in corrugated pad can be put between the two inner flaps.

This is a considerably efficient style for many industries. There is very little production waste during the die-cutting. The RSC carton can be used for most products and is one of the most common box styles. The Corrugated RSC carton is widely used as the shipping carton in all industries due to the low costs and easy assembling.

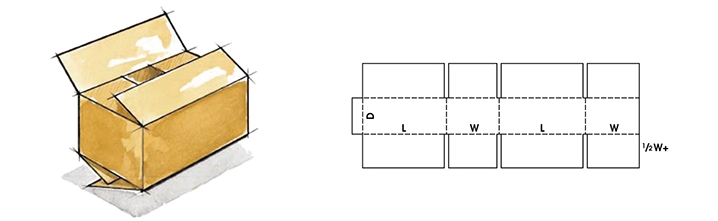

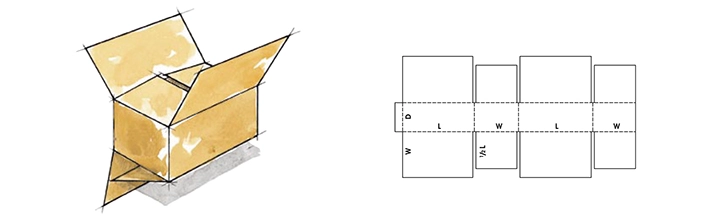

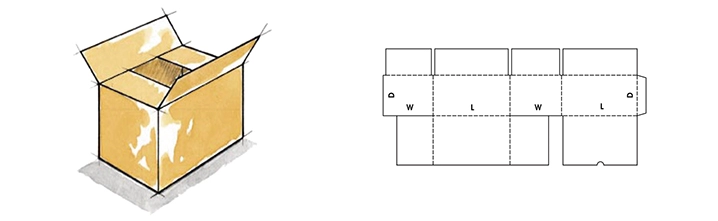

The OSC corrugated box is mainly used for the packing of the heavy-weight products with the better strength for protection. The length for all flaps are equal. The outer flaps overlap by one inch or more. The closure of the box is quite easy, usually with staples driven through the overlap area. This box style is usually applied when the length of the box is much greater than the width, creating a long gap between the two inner flaps. The sealed overlap helps to prevent the outer flaps from pulling apart.

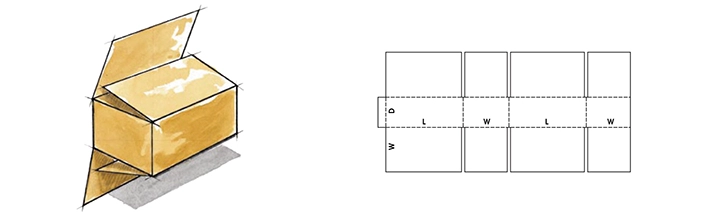

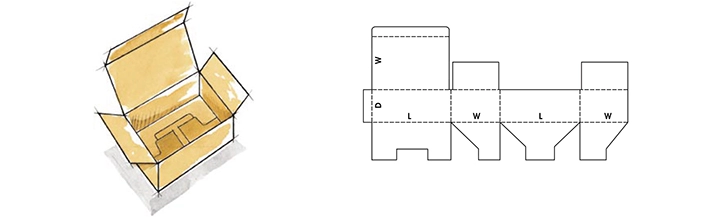

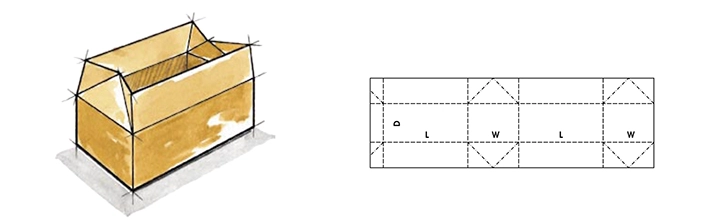

The FOL corrugated box provides the superior protection to the heavyweight products, like glasses, electronic gears. All flaps have the same length, which is equal to the width of the box. When set up, the outer flaps come within one inch of complete overlap. The carton style is especially resistant to rough handling and stacking. Stacked on its bottom surface, the overlapping flaps provide extra cushioning. Stacked on its side, the extra thickness provides added stacking strength.

Inner and outer flaps are scored and slotted to different lengths. Both pairs of flaps meet at the center of the box. The carton is especially sturdy because both top and bottom have double the thickness of corrugated fiberboard. The inner flaps, with no gap, provide an even and flat base for the product inside. A variation of this carton is the Side Special Slotted Carton, or SSS. All pairs of flaps meet, but not at the center of the box.

All flaps are equal to one-half the box length. The box length can be no more than twice its width. When closed, the inner flaps meet at the center of the box, giving a smooth and even base and full top protection. Depending on the ratio of length to width, the outer flaps overlap at random, up to full overlap.

The inner flaps and outer flaps are scored and slotted to the different lengths on the die-cutter. When folded, the inner flaps meet at the center of the box, and outer flaps completely overlap. With three full layers of combined board over the entire top and bottom, this style provides added cushioning when stacked on its bottom, or added stacking strength when stacked on its side. This style is particularly suitable for the heavy duty shipping and packaging.

Most used to make the E flute, B flute corrugated printed boxes. The flaps of bottom panel are creatively cut. To assemble, the workers fold the largest bottom panel first, then the two end panels. When the remaining bottom panel is folded and pressure is applied near the center, the flap "snaps" into the slot created by the other panels. The style is ideal for the light-weight products packaging. Because the box bottom is not completely sealed, it may not be ideal for heavy products.

The style is much the same as the tuck top snap bottom carton box above. The tuck top is replaced by the RSC top.

The integral divider provides the added cushioning to protect the products. The box style is particularly suitable for the liquid products packaging, beer and wine bottles, plastic containers and etc. Most wine shipping cartons have the dividers or partitions inside to protect the wine bottles.

When assembled, this carton box provides an interlocking thickness on its bottom and on its end panels. The style is widely applied in the kitchenware products packaging of the medium weight.

All flaps on the top and bottom of the box are connected as a whole piece. When folded, the staples are driven through the center of the carton. This style has a very tight closure on the top and bottom.

Copyright by CHINA BBP CO., LTD. All rights reserved.