There are 4 main reasons to explain why people choose cartons and paper boxes.

COMMUNICATION

Advertising

Cartons, or cardboard boxes are part of the advertising mix for products as they are displayed at the point of sale – in the shop as well as on the internet. It is estimated that about 75% of purchasing decisions in store are made right in front of the shelf – so a carton boxes can help ensure that a product is seen and then purchased. In a survey with both consumers and experts, it was established that packaging was seen to be the most effective form of advertising to persuade consumers to buy a product again.

Brand recognition

Cartons, paper boxes, have a high quality image, offer strong shelf impact and are highly regarded by the consumer. Innovative shapes and interesting print finishes combine to offer instant attraction and ensure brand recognition is maximized. The graph below shows what percentage of respondents correctly recognized the brand at differing time periods. It can be clearly seen that the product packed in a paper box was recognized much faster by more people than the product packaged in plastic.

Consumer appeal

Cartons and cartonboard are well liked by consumers and in a study by the Karmasin Institute, it was found that cartons, rigid paper boxes have a reliable and safe image. In addition, a further study showed that elderly people, who now account for a much larger proportion of consumers, found printed paper boxes much easier to recognise, open and use than other forms of packaging. Cartons project quality and consumers then tend to relate this to the product so giving carton packed products a better chance of success.

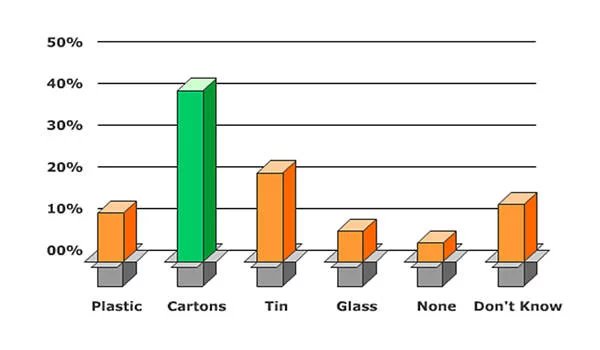

Consumer favourite

Consumers like cartons. They trust them and find them easier to use than other forms of packaging. In addition they are easy to crush and recycle and folding cartons have an excellent record with facilities in place all over Europe to recover them and return them for recycling. And consumers regard cartons as eco-friendly: Market research carried out by Audience Selection showed that consumers consider paper cartons to be the most environmentally friendly packaging option. Studies have shown that consumers like the feel of paper boxes and value their environmental credentials.

The graphics of a folding carton can provide a co-ordinated link reinforcing other media promotion of the brand by the brand owner through newspapers, magazines and television. Packaging is almost as popular as television as a means to promote the brand and packaging is best for stimulating repeat purchases. Cartons are-well known and liked by consumers and elicit a warm emotional response.

Information

With an ever increasing amount of information on packaging, cartons are best placed to provide clear and easier to read information than other packaging. This particularly appeals to the over 60 age group who wish not to have anything special done for them but would like to be able to use conventional packaging. Carton boxes deliver on this. They also offer excellent brand visibility which is helpful to all shoppers and also to the brand owners and retailers.

SUSTAINABILITY

The cartonboard and carton industry have a great environmental story to tell. Cartons are made from a renewable resource, compostable and easily recyclable, with decreasing production emissions.

Renewable Resources

The original raw material used for carton manufacture is wood fibre from sustainably managed forests. Additionally, at the end of life, cartons are collected and recycled and form a secondary raw material. About 49% of cartons in Europe are made from virgin fibre and 51% from recycled fibre.

Sustainable Forest Management

Around 80% of the wood fibres used in the European paper and board industry come from European forests, mainly in Sweden and Finland. European forests used by the paper and board industry are sustainable since annual growth of new wood exceeds the amount harvest by a large margin. Each year, European forests increase in size by an area equivalent to more than twice the size of London, or to put it another way 1,500 football pitches per day! Forest owners and operators carefully manage forests and can prove this through certification schemes such as the Forest Stewardship Council FSC ® and the Programme for the Endorsement of Forest Certification PEFC™.

The paper and board industry uses forest thinnings and only part of the mature tree: the small diameter tops of large trees and saw mill waste. No tropical rain forests are destroyed in order to make paper and board.

Recovery and Recycling

Folding cartons and corrugated boxes can easily be recycled by reprocessing in a mill, where the fibres are separated. The recovered fibre is then used to make cartonboard or another paper or board product. Alternatively, they can either be composted, a process also known as “organic recycling”, or if recycling is no longer a viable option, their energy content can be recovered in an energy-from-waste incinerator.

For recycling to happen, the packaging waste must be recovered, i.e. collected and sent to a mill. Cartons together with other paper products may be segregated in the home, or other point of disposal, and either collected or taken to a collecting location. Efficient recovery and recycling systems are in place in Europe which deliver excellent results: paper and board is the most recycled packaging material in the EU with a recycling rate of 85%, based on 2016 data from Eurostat.

Biogenic Carbon

Carbon dioxide is the most common greenhouse gas and a major contributor to climate change. Cartons’ raw material comes from sustainably managed trees which grow by absorbing carbon dioxide and storing carbon – this process is measured in terms of biogenic carbon. By removing carbon from the atmosphere trees help to reverse the greenhouse effect and this filtering process delivers a sustainable, renewable, bio-based raw material for cartons.

Carbon Footprint

The carbon footprint of cartons is the measurement of the effect of their production process on the environment. Pro Carton has measured the European cartonboard and carton industry’s production processes over several years and has recorded its improving environmental performance and a year on year decrease in its carbon footprint.

Energy Use

The European pulp, paper and board industry is a leader in sustainable energy use. 56% of all primary energy used in the industry is biomass based, with the wood by-products providing renewable energy in the form of electricity and steam for the manufacturing process. It is the largest producer and consumer of biomass based energy – 20% of the EU total – thus avoiding the use of non-renewable energy sources such as fossil-based oil, coal or gas.

Water Use

Water is an essential element for paper and board production and is usually taken by a mill from a nearby surface source such as a lake or river. 95% of the water used in the European industry is cleaned and reused on site. All waste water is purified at the mill in accordance with European regulations and standards, before being returned to the environment. Mills are working to reduce process water use as this makes good economic as well as environmental sense and the trend over the past two decades has been to reduce fresh water withdrawal by 20% in total volume.

©Mayr-Melnhof Karton GmbH.

SAFETY

Consumer Security

Security is becoming increasingly important throughout the supply chain. Paper boxes can be designed to incorporate a wide range of security systems, based on both covert and overt technologies. Designs can include tamper-evidence, child-resistance or other security benefits through tagging mechanisms, creative constructional design as well as print and ink system technologies. The variety of these systems also helps in reducing losses providing brand owners and retailers with greater levels of confidence. The increasing problem of counterfeiting can also be helped using the technology available to carton and cartonboard manufacturers and this offers consumers confidence in the products they buy.

Protection

Cartons, in particular, contribute a very small percentage of the price paid by the consumer at the point of purchase – less than 5 % for most products and for some products, such as medicines, less than 0.1 %. Would prices fall if there was no packaging? No – prices would rise! Without the benefits of modern packaging, supermarkets could not handle, store and display the range of products they now offer and the cost of transportation and storage together with handling at the point of sale would inevitably rise. The environmental impact of packaging as a result of its manufacture and use, together with the implications of its ultimate disposal, must be balanced against the benefits it provided in preventing the waste of more expensive resources, especially of food.

Counterfeiting Security

Counterfeiting harms both a brand’s reputation and the consumer of counterfeited products. Folding cartons can offer overt (visible), covert (non-visible) and track-and-trace technology to help brands protect themselves. An example of visible protection is an embossed hologram on a varnish layer which can show overt security features alongside the decoration. Using a substrate with integral coloured identification can provide covert protection. The security features can also be embedded in the cartonboard and thus be very difficult to imitate by printing. Cartons can offer printed RFID systems for authentication and track- and-trace of product. The electronic element is produced with conductive inks and can be integrated with the carton structure.

Cartons – a safe packaging solution made from a sustainable material

Consumer health and safety is the top priority for the cartonboard and carton industries. Every care is taken to prevent the migration of unwanted substances such as mineral hydrocarbons from cartons into food. Despite the fact that no clear evidence has been presented to support the recent concern over the presence of mineral hydrocarbons, the industries have been finding solutions to address the issue.

From the perspective of the cartonboard substrate, depending on the overall packaging system and after thorough risk assessment, different solutions are possible, both on the basis of primary fibre cartonboard and of recycled grades with and without functional barriers.

Good Manufacturing Practice guidelines have been established for carton makers. A guidance document¹ provides practical advice to packaging box printers and converters covering the entire carton production process with the aim of preventing health hazards or unacceptable changes in food as a result of migrations.

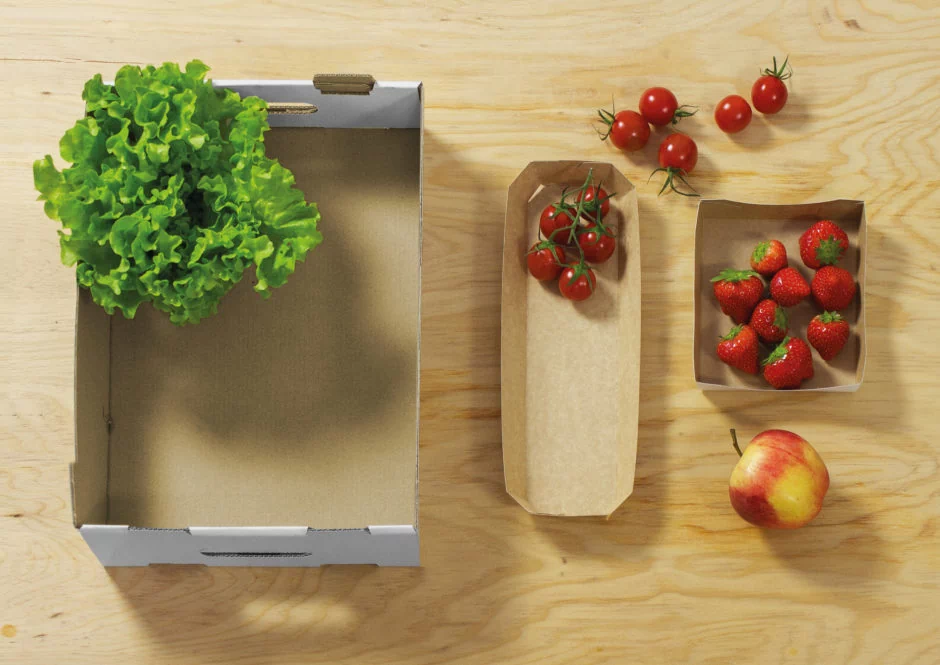

Protection against Food Waste

Packaging, including cartons, is key to protecting the resources embedded in manufactured goods. This is especially true in the food industry, where dealing with the issue of Food Waste and wasted resources, is becoming a priority.

Cartonboard packaging adds value to a product; increasing its overall resource efficiency through reducing food waste. By protecting food and reducing food waste, cartons contribute to more sustainable consumption and benefit society by making our modern, convenience-driven lifestyles possible.

In Europe, 62% of folding cartons produced are used to package food.

Cartonboard packaging: made from a sustainable, renewable resource

The original resource of the cartonboard industry is the natural, renewable forest. European forests used by the paper and board industry are sustainable. Every year new growth exceeds the wood harvested by an area equivalent to over 500,000 football pitches. The volume of European forests doubled from 1950 to 2000.

Paper and board packaging is easy to collect and recycle. In recycled cartonboard production, fibres can be recycled more than 25 times2 , with an input of fresh fibres from virgin fibre products which provide a valuable raw material for recycled products. Production of packages with recycled content would not be possible without virgin fibres, and it is only with a simultaneous presence on the market of primary and secondary fibres that a viable fibre cycle that is both economic and ecological, can be maintained.

Cartonboard manufacturers aim for continuous improvement by using less wood and energy and so becoming more resource-efficient. Also, the development of lighter base weights means the use of less packaging overall and less waste.

©Mayr-Melnhof Karton GmbH.

¹ “European Guide to Good Manufacturing Practice for Cartonboard based Food Packaging“, European Carton Makers Association (ECMA)

2 Source TU Darmstadt